Product

Pipes

Fittings

PVC Suction Hose

PVC Pipes for agricultural use are lightweight, durable, and resistant to chemicals, making them ideal for irrigation systems. They ensure smooth water flow, easy installation, and long-term performance in farms, fields, and greenhouses.

- High Flow Efficiency

- UV Resistant Material

- Leak-Proof Joints

- Lightweight & Strong

- Easy to Install

- Long-Term Durability

SPECIFICATIONS

| Outside Diameter (mm) | Tolerance on Outside Diameter (mm) | Class 1 2.5 kg/cm² |

Class 2 4 kg/cm² |

Class 3 6 kg/cm² |

Class 5 10 kg/cm² |

Plumbing Pipes | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | ||

| 20 | +0.3 | – | – | – | – | – | – | 1.1 | 1.5 | 2.8 | 3.3 |

| 25 | +0.3 | – | – | – | – | – | – | 1.4 | 1.8 | 2.9 | 3.4 |

| 32 | +0.3 | – | – | – | – | 1.4 | 1.8 | 1.8 | 2.2 | 3.4 | 3.9 |

| 40 | +0.3 | – | – | – | – | 1.7 | 2.1 | 2.3 | 2.8 | 3.7 | 4.3 |

| 50 | +0.3 | – | – | – | – | 2.0 | 2.4 | 2.9 | 3.5 | 4.3 | 5.0 |

| 63 | +0.3 | – | – | 1.5 | 1.9 | 2.4 | 3.0 | 3.6 | 4.4 | – | – |

| 75 | +0.3 | – | – | 1.8 | 2.2 | 2.6 | 3.1 | 4.2 | 5.0 | – | – |

| 90 | +0.3 | 1.3 | 1.7 | 2.1 | 2.6 | 3.1 | 3.7 | 5.0 | 6.0 | – | – |

| 110 | +0.4 | 1.6 | 2.0 | 2.5 | 3.0 | 3.7 | 4.3 | 6.2 | 7.4 | – | – |

| 140 | +0.5 | 2.0 | 2.4 | 3.2 | 3.8 | 4.8 | 5.7 | 7.7 | 9.0 | – | – |

| 160 | +0.6 | 2.3 | 2.8 | 3.7 | 4.4 | 5.5 | 6.5 | 8.8 | 10.2 | – | – |

| 200 | +0.6 | 2.9 | 3.4 | 4.6 | 5.4 | 6.9 | 8.1 | 11.0 | 12.8 | – | – |

| 225 | +0.7 | 3.3 | 3.9 | 5.2 | 6.0 | 7.6 | 8.8 | 12.4 | 14.5 | – | – |

| 250 | +0.7 | 3.7 | 4.3 | 5.8 | 6.7 | 8.5 | 9.8 | 13.8 | 16.1 | – | – |

| 280 | +0.8 | 4.1 | 4.8 | 6.4 | 7.4 | 9.5 | 11.0 | 15.5 | 18.1 | – | – |

| 315 | +0.9 | 4.6 | 5.3 | 7.2 | 8.3 | 10.7 | 12.4 | 17.4 | 20.4 | – | – |

| 355 | +1.1 | 5.1 | 5.9 | 8.1 | 9.4 | 12.0 | 13.8 | 19.6 | 22.6 | – | – |

| 400 | +1.2 | 5.8 | 6.7 | 9.1 | 10.5 | 13.5 | 15.6 | 22.0 | 25.3 | – | – |

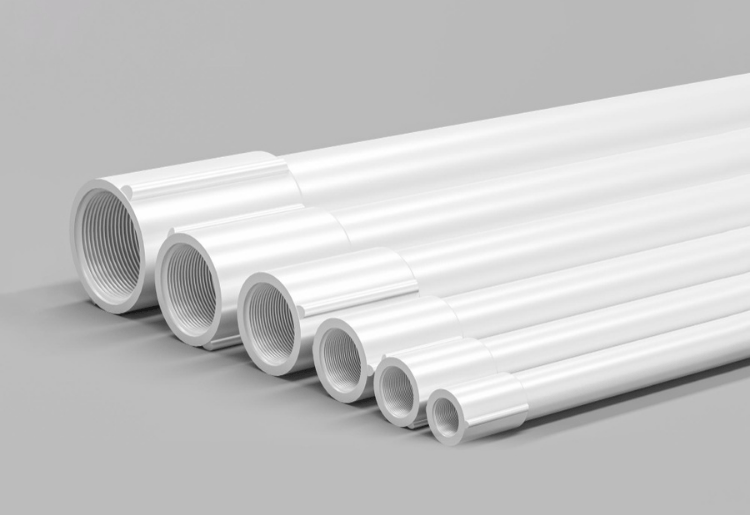

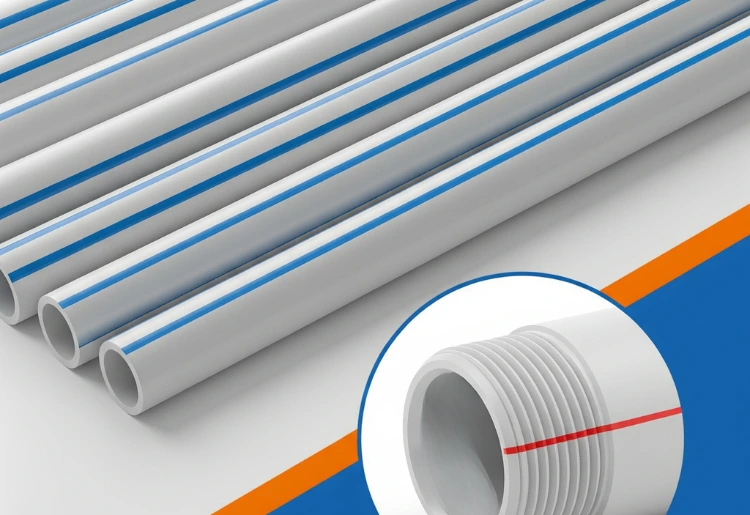

PVC Column Pipes are designed for submersible pumps in borewells, offering high strength and pressure resistance. Their threaded ends ensure secure fittings, while their non-corrosive and lightweight nature makes them ideal for deep water lifting applications.

- High Load Capacity

- Leak-Proof Threads

- Corrosion Free Performance

- Easy to Handle

- Long Service Life

- Suitable for Borewells

SPECIFICATIONS

| Dimensional Specification (Coupler Type) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Class | Printing Colour | Wall Thickness in MM | OD | Pressure Rating (kg/cm²) |

Packing (Nos.) |

Safe Pulling Load with Chain Pully (kgf) |

Safe Pump Delivery Head | |||

| End Min. / Max | Middle Min. / Max | (Mtr.) | (Ft.) | ||||||||

| 25 mm | V4 12.5 | Orange | 3.7 / 4.2 | 2.0 / 2.5 | 33.0 | 12.5 | 25 | 600 | 125 | 410 | |

| 25 mm | V4 15 | Purple | 3.7 / 4.2 | 2.3 / 2.8 | 33.0 | 15 | 25 | 600 | 150 | 492 | |

| 32 mm | V4 12.5 | Orange | 4.1 / 4.6 | 2.5 / 3.0 | 42.0 | 12.5 | 20 | 800 | 125 | 410 | |

| 32 mm | V4 15 | Purple | 4.1 / 4.6 | 2.6 / 3.1 | 42.0 | 15 | 20 | 900 | 150 | 492 | |

| 40 mm | V4 12.5 | Orange | 4.6 / 5.1 | 2.6 / 3.1 | 48.0 | 12.5 | 20 | 1000 | 125 | 410 | |

| 40 mm | V4 15 | Purple | 4.6 / 5.1 | 3.1 / 3.6 | 48.0 | 15 | 20 | 1200 | 150 | 492 | |

| 32 mm | Medium | Red | 6.4 / 7.0 | 4.0 / 4.5 | 42.0 | 15 | 20 | 250 | 120 | 400 | |

| 32 mm | Standard | Blue | 7.1 / 7.6 | 4.4 / 5.0 | 42.0 | 20 | 20 | 400 | 135 | 444 | |

| 32 mm | Heavy | Black | 7.6 / 8.1 | 4.8 / 5.3 | 42.0 | 25 | 20 | 800 | 150 | 492 | |

| 32 mm | Super Heavy | Black | 8.1 / 8.6 | 5.3 / 5.8 | 42.0 | 32 | 20 | 1200 | 165 | 544 | |

| 40 mm | Medium | Red | 6.5 / 7.1 | 4.1 / 4.6 | 48.0 | 15 | 20 | 300 | 120 | 400 | |

| 40 mm | Standard | Blue | 7.1 / 7.6 | 4.4 / 5.0 | 48.0 | 20 | 20 | 500 | 135 | 444 | |

| 40 mm | Heavy | Black | 7.6 / 8.1 | 4.8 / 5.3 | 48.0 | 25 | 20 | 1000 | 150 | 492 | |

| 40 mm | Super Heavy | Black | 8.1 / 8.6 | 5.3 / 5.8 | 48.0 | 32 | 20 | 1500 | 165 | 544 | |

| 50 mm | Medium | Red | 6.7 / 7.3 | 4.2 / 4.7 | 60.0 | 15 | 10 | 500 | 120 | 400 | |

| 50 mm | Standard | Blue | 7.3 / 7.8 | 4.5 / 5.1 | 60.0 | 20 | 10 | 800 | 135 | 444 | |

| 50 mm | Heavy | Black | 7.8 / 8.3 | 5.0 / 5.5 | 60.0 | 25 | 10 | 1500 | 150 | 492 | |

| 50 mm | Super Heavy | Black | 8.3 / 8.8 | 5.5 / 6.0 | 60.0 | 32 | 10 | 2000 | 165 | 544 | |

| 65 mm | Medium | Red | 6.8 / 7.4 | 4.2 / 4.7 | 75.0 | 15 | 5 | 800 | 120 | 400 | |

| 65 mm | Standard | Blue | 7.4 / 7.9 | 4.6 / 5.1 | 75.0 | 20 | 5 | 1200 | 135 | 444 | |

| 65 mm | Heavy | Black | 7.9 / 8.4 | 5.0 / 5.5 | 75.0 | 25 | 5 | 1800 | 150 | 492 | |

| 65 mm | Super Heavy | Black | 8.4 / 8.9 | 5.5 / 6.0 | 75.0 | 32 | 5 | 2500 | 165 | 544 | |

| 80 mm | Medium | Red | 6.8 / 7.4 | 4.2 / 4.7 | 90.0 | 15 | 5 | 1000 | 120 | 400 | |

| 80 mm | Standard | Blue | 7.4 / 7.9 | 4.6 / 5.1 | 90.0 | 20 | 5 | 1500 | 135 | 444 | |

| 80 mm | Heavy | Black | 7.9 / 8.4 | 5.0 / 5.5 | 90.0 | 25 | 5 | 2500 | 150 | 492 | |

| 80 mm | Super Heavy | Black | 8.4 / 8.9 | 5.5 / 6.0 | 90.0 | 32 | 5 | 3000 | 165 | 544 | |

| 100 mm | Medium | Red | 8.4 / 9.0 | 5.3 / 5.9 | 108.0 | 15 | 2 | 1200 | 120 | 400 | |

| 100 mm | Standard | Blue | 9.0 / 9.6 | 5.7 / 6.3 | 108.0 | 20 | 2 | 2500 | 135 | 444 | |

| 100 mm | Heavy | Black | 9.6 / 10.1 | 6.2 / 6.7 | 108.0 | 25 | 2 | 3000 | 150 | 492 | |

| 100 mm | Super Heavy | Black | 10.1 / 10.6 | 6.7 / 7.2 | 108.0 | 32 | 2 | 4000 | 165 | 544 | |

Borewell Casing Pipes are used to support the walls of boreholes and prevent collapse during water extraction. Made from high-strength PVC, they are corrosion-resistant, lightweight, and easy to install, ensuring long-lasting performance in deep well applications.

- Strong Wall Support

- Non-Corrosive Material

- Easy to Install

- Long-Term Durability

- Light in Weight

- Ideal for Borewells

| Nominal Diameter (DN) | Mean Outer Diameter (d) of Pipe (mm) | Wall Thickness (mm) | ||||

|---|---|---|---|---|---|---|

| Min | Max | Type – CM | Type – CS | |||

| 1½" / 40 | 48.00 | 48.20 | 3.50 | 4.00 | – | – |

| 2" / 50 | 60.00 | 60.20 | 4.00 | 4.60 | – | – |

| 3" / 80 | 88.00 | 88.30 | 4.00 | 4.60 | – | – |

| 4" / 100 | 113.00 | 113.30 | 5.00 | 5.70 | 4.00 | 4.40 |

| 5" / 125 | 140.00 | 140.40 | 6.50 | 7.30 | 4.90 | 5.40 |

| 6" / 150 | 165.00 | 165.40 | 7.50 | 8.50 | 5.70 | 6.50 |

| 7" / 175 | 200.00 | 200.50 | 8.80 | 9.80 | 7.00 | 7.80 |

| 8" / 200 | 225.00 | 225.50 | 10.00 | 11.20 | 7.60 | 8.80 |

| 10" / 250 | 280.00 | 280.50 | 12.50 | 14.00 | 9.60 | 11.00 |

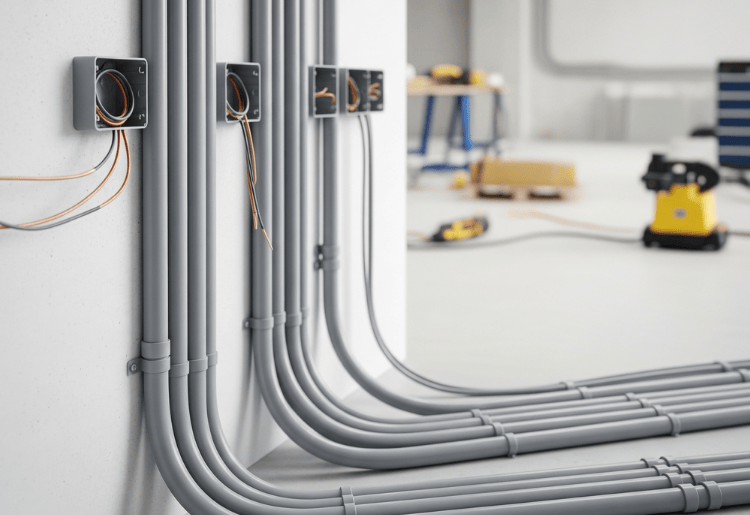

PVC Conduit Pipes are used to protect and route electrical wiring in residential, commercial, and industrial buildings. They are non-conductive, lightweight, flame-retardant, and resistant to moisture, ensuring safe and long-lasting electrical installations in any environment.

- Flame Retardant Material

- Non-Conductive Surface

- Moisture Resistant Build

- Easy Cable Routing

- Lightweight and Durable

- Suitable for Wiring

Sprinkler Irrigation Systems provide efficient water distribution for agricultural fields, lawns, and gardens. Designed for uniform coverage, these systems help conserve water, reduce labor, and improve crop yield by delivering moisture directly to plant roots in controlled patterns.

- Uniform Water Distribution

- Saves Water Efficiently

- Easy to Install

- Low Maintenance Cost

- Suitable for Crops

- Reduces Manual Labor

PVC Suction Hose Pipes are flexible, durable, and designed for suction and delivery of water, slurry, and light chemicals. Commonly used in agriculture and industry, these hoses offer excellent strength, transparency, and resistance to abrasion and corrosion.

- Flexible and Strong

- Abrasion Resistant Material

- Transparent for Flow

- Lightweight and Durable

- Corrosion Free Build

- Ideal for Suction

SPECIFICATIONS

| Normal Size | Diameter | Bending Radius (mm) |

Pressure (at 30°C) | Standard Lengths (mtrs.) |

||

|---|---|---|---|---|---|---|

| Inches | ID mm / OD mm | Working kg/cm² | Bursting kg/cm² | |||

| ¾ | 20 | 19.0 ± 0.5 / 23.6 ± 1.0 | 45 | 7.0 | 24.0 | 30/50 |

| 1 | 25 | 25.4 ± 0.5 / 30.0 ± 1.0 | 55 | 7.0 | 23.0 | 30/50 |

| 1¼ | 30 | 31.8 ± 0.5 / 36.8 ± 1.0 | 75 | 6.5 | 20.0 | 30/50 |

| 1½ | 40 | 38.0 ± 0.5 / 43.3 ± 1.0 | 95 | 5.0 | 16.0 | 30/50 |

| 2 | 50 | 50.8 ± 0.5 / 57.8 ± 1.5 | 122 | 4.0 | 16.0 | 30/45/50 |

| 2½ | 65 | 63.5 ± 1.0 / 72.0 ± 1.5 | 160 | 4.0 | 16.0 | 30/45 |

| 3 | 75 | 76.2 ± 1.0 / 85.0 ± 1.5 | 272 | 3.5 | 15.0 | 30/36 |

| 4 | 100 | 101.2 ± 1.0 / 112.2 ± 2.0 | 290 | 3.5 | 11.0 | 15/18/30 |

| 5 | 125 | 126.8 ± 1.5 / 141.0 ± 2.0 | 230 | 3.0 | 10.0 | 15/18 |

| 6 | 150 | 152.4 ± 1.5 / 169.4 ± 2.0 | 375 | 2.5 | 9.0 | 15/18 |

| 8 | 200 | 203.2 ± 2.0 / 224.4 ± 2.0 | 600 | 2.5 | 8.0 | 4.5/6 |

| 10 | 250 | 254.0 ± 2.0 / 284.0 ± 2.0 | 1000 | 2.5 | 8.0 | 4.5/6 |

| 12 | 300 | 304.0 ± 2.0 / 340.0 ± 2.0 | 1000 | 2.5 | 6.0 | 4.5/6 |

Recommended Maximum working temperature: 60/70°C

PVC Tubing Flexible Pipes are lightweight, transparent, and highly flexible, ideal for low-pressure fluid transfer in agriculture, laboratories, and domestic applications. They are easy to handle, kink-resistant, and made from non-toxic materials for safe usage.

- Highly Flexible Design

- Transparent and Clear

- Kink Resistant Tube

- Non-Toxic Material

- Easy to Handle

- Multipurpose Fluid Transfer

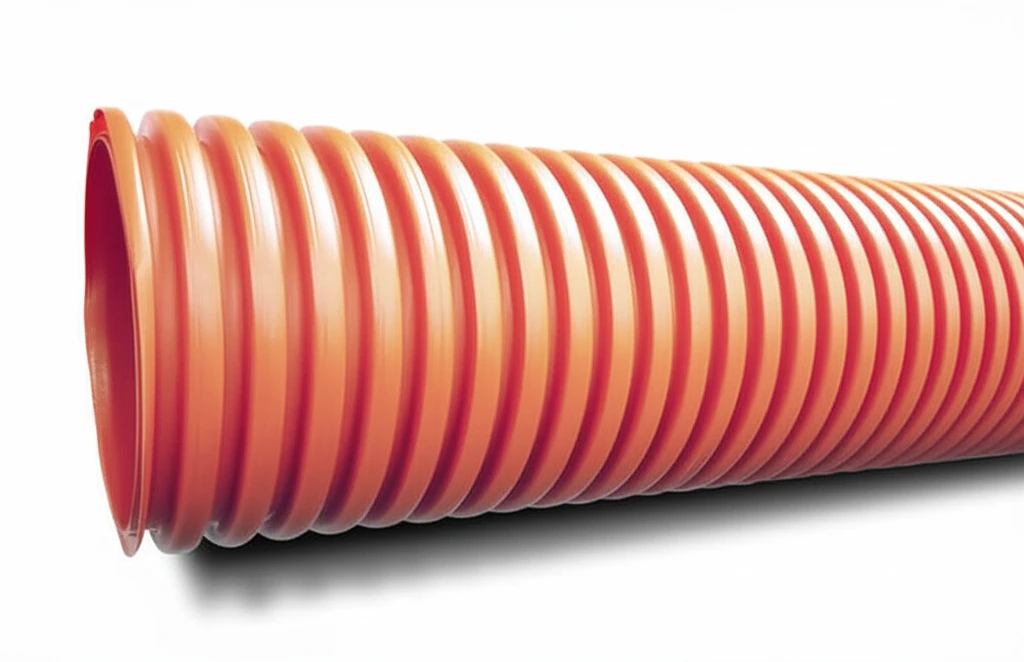

DWC (Double Wall Corrugated) pipes are high-strength, lightweight piping solutions made from high-density polyethylene (HDPE), designed with a smooth inner surface and a corrugated outer layer. These pipes are widely used for underground cable protection, drainage systems, and sewage applications due to their excellent mechanical strength and flexibility. DWC pipes are UV resistant, non-corrosive, and capable of withstanding heavy external loads, making them ideal for telecom, power cable ducting, and infrastructure development.

- Strong Yet Lightweight Double Wall Structure

- Ideal for Underground Cable Ducting & Drainage

- Corrosion, UV & Chemical Resistant

- High Ring Stiffness – Withstands Heavy Loads

- Smooth Inner Wall for Easy Cable Pulling

- Long Life with Minimal Maintenance

SPECIFICATIONS

| Duct Size / Nominal OD (mm) | Nominal ID (mm) | Standard Length (Mtrs) |

|---|---|---|

| 50 | 38 | 6 |

| 63 | 51 | 6 |

| 75 | 63 | 6 |

| 90 | 76 | 6 |

| 110 | 96 | 6 |

| 120 | 103 | 6 |

*Specific sizes can be supplied in coil form on request.

cPVC (Chlorinated Polyvinyl Chloride) pipes are specially designed for hot and cold water distribution systems. Manufactured to withstand high temperatures and pressure, these pipes are ideal for residential, commercial, and industrial plumbing. They offer excellent resistance to corrosion, scaling, and chemical degradation, ensuring long-term durability and clean water supply. Easy to install with solvent cement jointing, cPVC pipes are a reliable and cost-effective solution for modern plumbing needs.

- Withstands High Temperatures & Pressure

- Corrosion & Chemical Resistant

- Smooth Inner Surface – No Scaling

- Ideal for Hot & Cold Water Applications

- Quick & Easy Installation with Solvent Cement

- Long Service Life with Low Maintenance

SPECIFICATIONS

| Nominal Pipe Size | Outer Diameter in (mm) | SDR 11 | SDR 13.5 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Wall Thickness in (mm) | Working Pressure | Wall Thickness in (mm) | Working Pressure | ||||||

| inch / mm | Average ± Tolerance | Min | Tolerance | 23°C | 82°C | Min | Tolerance | 23°C | 82°C |

| ½” / 15 | 0.625 (15.90) ±0.003 (±0.08) | 0.068 (1.73) | ±0.020 (±0.51) | 28.1 | 7.0 | 0.055 (1.40) | ±0.020 (±0.51) | 22.5 | 5.6 |

| ¾” / 20 | 0.875 (22.20) ±0.003 (±0.08) | 0.080 (2.03) | ±0.020 (±0.51) | 28.1 | 7.0 | 0.065 (1.65) | ±0.020 (±0.51) | 22.5 | 5.6 |

| 1” / 25 | 1.125 (28.60) ±0.003 (±0.08) | 0.102 (2.59) | ±0.020 (±0.51) | 28.1 | 7.0 | 0.083 (2.12) | ±0.020 (±0.51) | 22.5 | 5.6 |

| 1¼” / 32 | 1.375 (34.90) ±0.003 (±0.08) | 0.125 (3.18) | ±0.020 (±0.51) | 28.1 | 7.0 | 0.102 (2.59) | ±0.020 (±0.51) | 22.5 | 5.6 |

| 1½” / 40 | 1.625 (41.30) ±0.004 (±0.010) | 0.148 (3.76) | ±0.020 (±0.51) | 28.1 | 7.0 | 0.120 (3.06) | ±0.020 (±0.51) | 22.5 | 5.6 |

| 2” / 50 | 2.125 (54) ±0.004 (±0.010) | 0.193 (4.90) | ±0.023 (±0.58) | 28.1 | 7.0 | 0.157 (4.00) | ±0.023 (±0.58) | 22.5 | 5.6 |

| Size mm (inch) | Outer Diameter in (mm) | Schedule 40 Wall Thickness in (mm) | Schedule 80 Wall Thickness in (mm) |

|---|---|---|---|

| 65 (2.1/2") | 73.0 ± 0.18 (72.82 – 73.18) | 5.16 – 5.77 | 7.01 – 7.85 |

| 80 (3") | 88.9 ± 0.20 (88.7 – 89.1) | 5.49 – 6.15 | 7.62 – 8.53 |

| 100 (4") | 114.3 ± 0.23 (114.07 – 114.53) | 6.02 – 6.73 | 8.56 – 9.58 |

| 150 (6") | 168.3 ± 0.28 (168.02 – 168.58) | 7.11 – 7.97 | 10.97 – 12.29 |

Stronger, resilient & longer lasting,

easy transportation and install due to light

weight & secured threats ensuring leak

proof joints, optimum flow rate & flow

frictional loses, excellent chemical &

corrosion resistance; free from rusting,

pitting & scaling.

- Building Plumbing

- Water Distributor Mains

- Swimming Pool

- Salt Water Lines

- Plating Industry

- Sugar, Paper & Breweries etc.

SPECIFICATIONS

| NOMINAL BORE | MEAN OUTSIDE DIAMETER | PVC SCHEDULE 40 | PVC SCHEDULE 80 | ||

|---|---|---|---|---|---|

| Wall Thickness (min./max.) (mm) | Working Pressure at 23°C (kg/cm²) | Wall Thickness (min./max.) (mm) | Working Pressure at 23°C (kg/cm²) | ||

| ½” / 15 mm | 21.2 – 21.5 | 2.8 – 3.3 | 41.4 | 3.7 – 4.2 | 58.6 |

| ¾” / 20 mm | 26.6 – 26.8 | 2.9 – 3.4 | 33.1 | 3.9 – 4.4 | 47.6 |

| 1” / 25 mm | 33.3 – 33.6 | 3.4 – 3.9 | 31.1 | 4.6 – 5.0 | 43.4 |

| 1¼” / 32 mm | 42.0 – 42.3 | 3.6 – 4.1 | 25.5 | 4.9 – 5.4 | 35.9 |

| 1½” / 40 mm | 48.1 – 48.4 | 3.7 – 4.2 | 22.8 | 5.1 – 5.7 | 32.4 |

| 2” / 50 mm | 60.2 – 60.6 | 3.9 – 4.4 | 19.3 | 5.5 – 6.2 | 27.6 |

| 2½” / 63 mm | 72.8 – 73.2 | 5.2 – 5.8 | 20.7 | 7.0 – 7.8 | 29.0 |

| 3” / 75 mm | 88.7 – 89.1 | 5.5 – 6.1 | 17.9 | 7.6 – 8.5 | 25.5 |

| 4” / 100 mm | 114.1 – 114.5 | 6.0 – 6.7 | 13.6 | 8.6 – 9.6 | 22.1 |

| 6” / 150 mm | 168.3 – 168.5 | 7.1 – 7.9 | 12.4 | 11.0 – 12.3 | 19.3 |

| Pipe (inch) | ½″ | ¾″ | 1″ | 1¼″ | 1½″ | 2″ | 3″ | 4″ | 6″ |

|---|---|---|---|---|---|---|---|---|---|

| Size (mm) | 15 | 20 | 25 | 32 | 40 | 50 | 80 | 100 | 150 |

| No. of Joints/Ltr. | 274 | 169 | 148 | 106 | 74 | 42 | 32 | 21 | 6 |

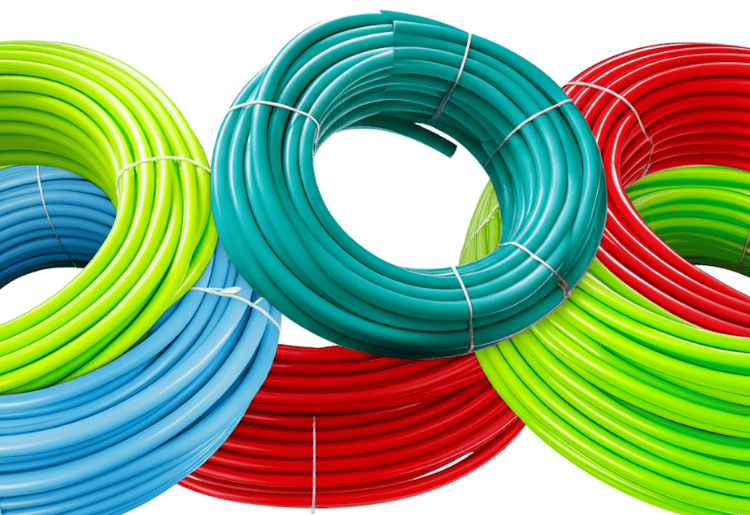

flexible to be used on any

surface, corrosion resistant, chemical and

abrasion resistant – can be used for acid and

alkalies, uv resistant, easy installation – Sizes

upto 110mm pipe is available in coil form of

250-300 meters. Coil lengths can be

increased incase of sizes from 20mm to

50mm OD, easy jointing, can be used on

high altitudes & temperature as low as 50°c,

low transportation, handling & installation

cost, expected life – min. 50 years.

- Highly Flexible Design

- Corrosion & Chemical Resistant

- UV & Abrasion Resistant

- Available in Long Coils (Up to 300m)

- Easy Jointing & Installation

- Expected Life: Minimum 50 Years

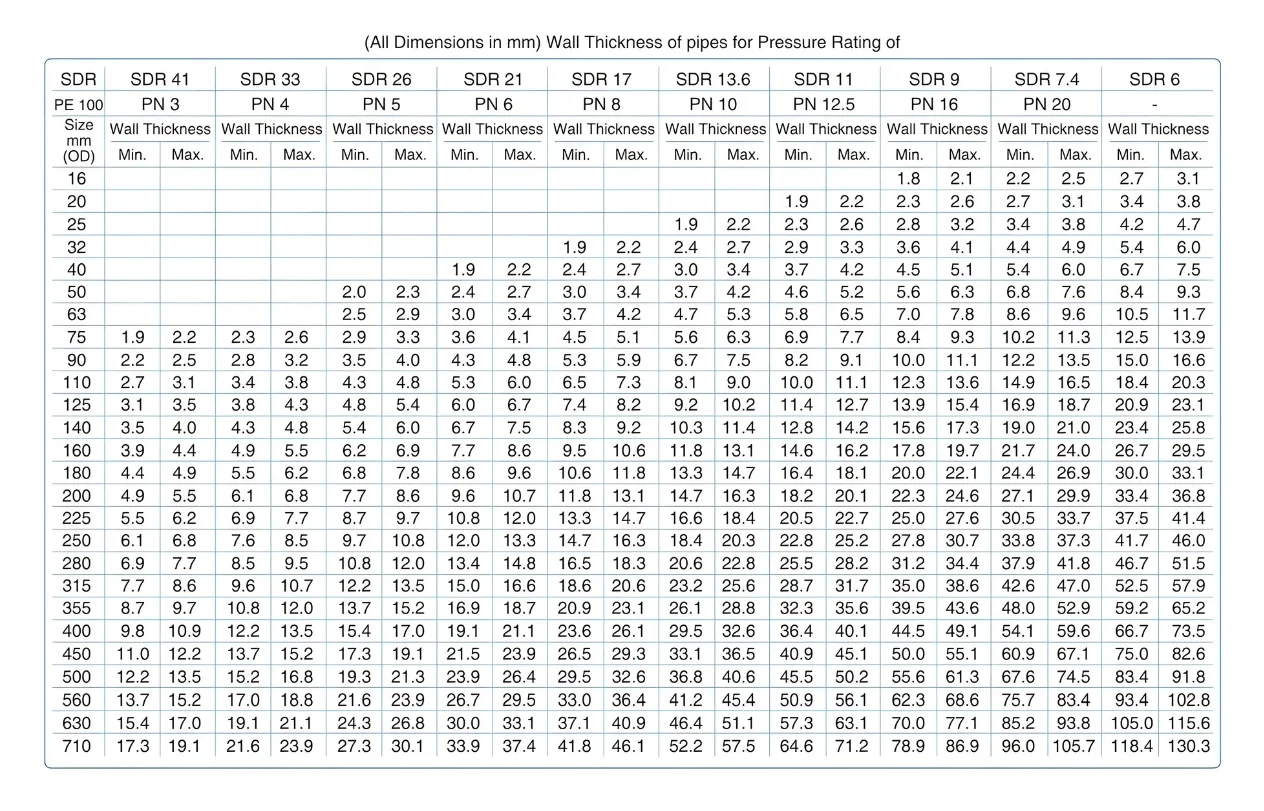

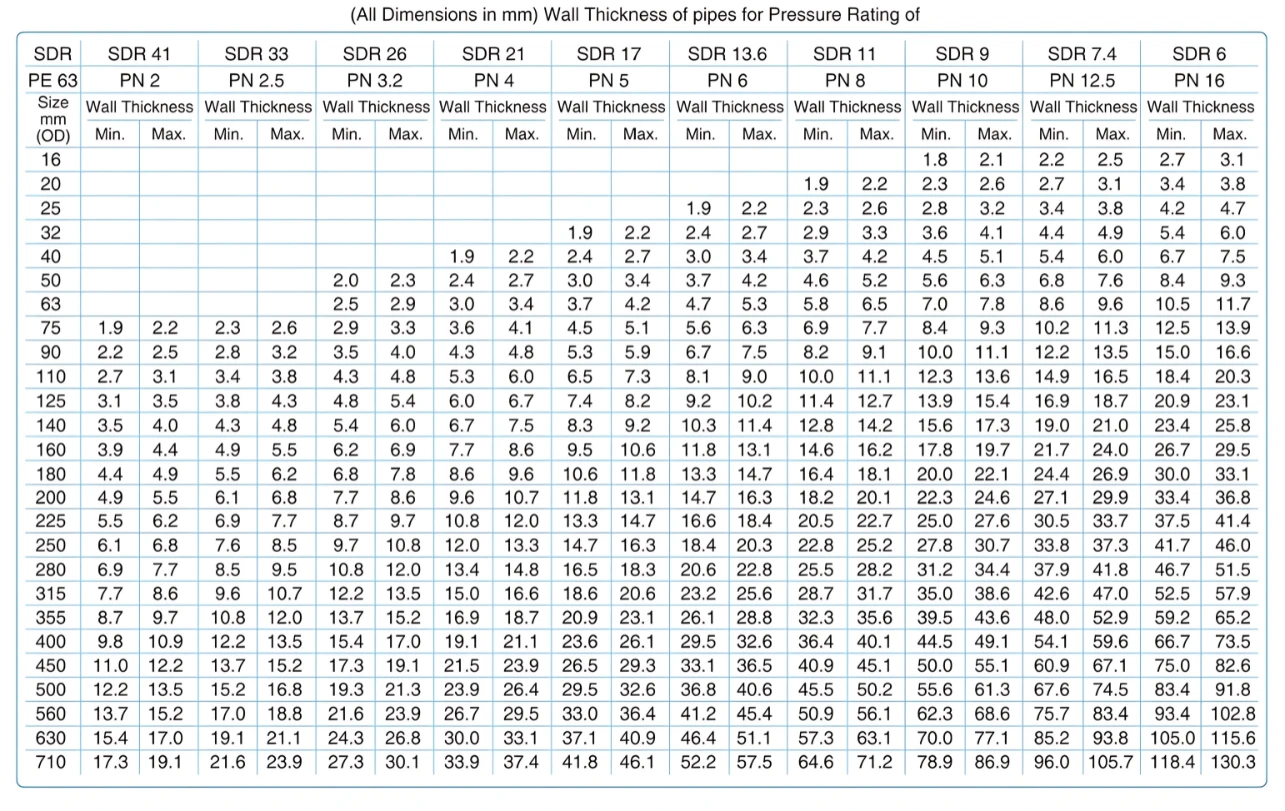

Material Grade PE 63

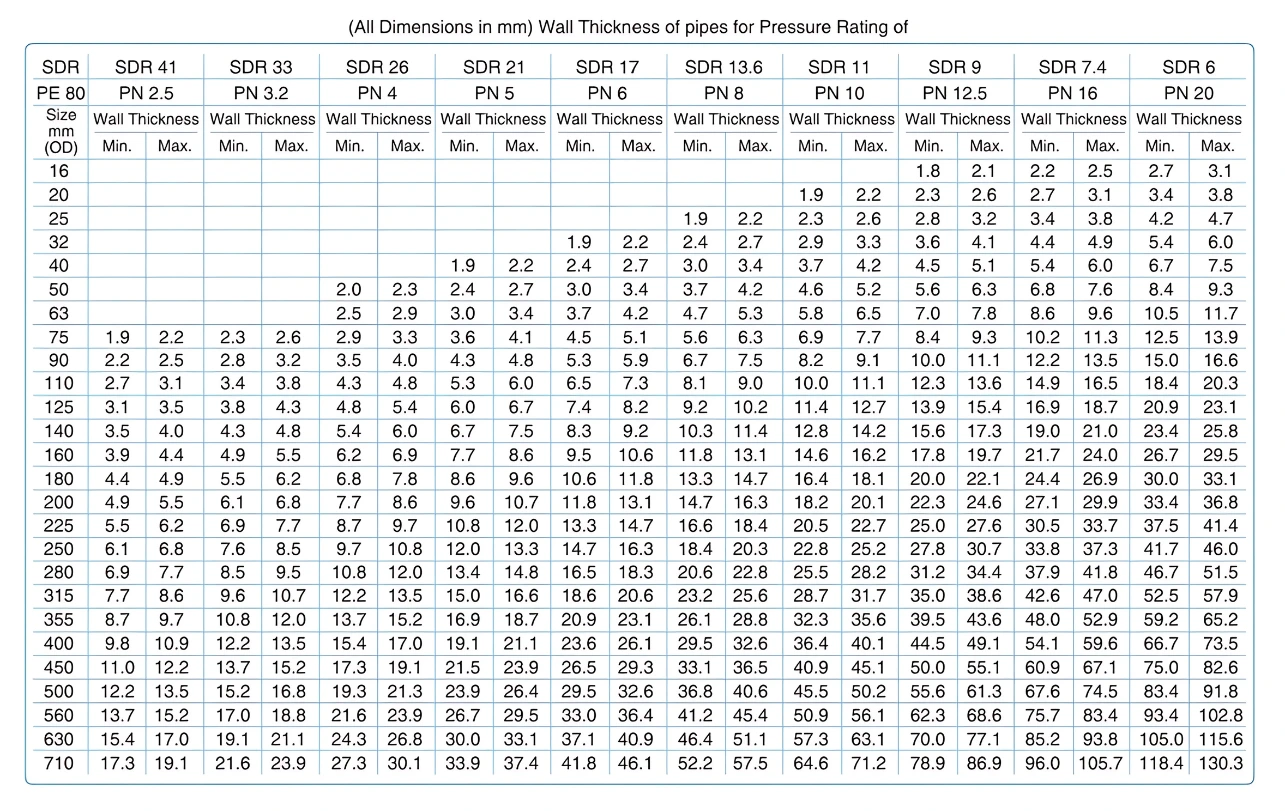

Material Grade PE 80

Material Grade PE 10